As a business that has been making and supplying lifting products for over 150 years, we know a thing or two about lifts and consider ourselves specialists in home lifts. For low-rise applications, electrically powered lifts are a reliable and cost-effective drive system with plenty of lifting force and in-built safety.

.jpg?width=768&height=512&name=Uplifts%20(1).jpg)

Traction vs. hydraulic lifts

Traction and rope and drum lifts use steel ropes to pull the lift up, either by winding the rope onto a drum or using counterweights. A hydraulic lift pumps fluid into a ram that pushes a lift up, when the lift descends the fluid flows back into the reservoir. As with everything in life each system has pros and cons.

At Stannah, we have chosen electrically powered to drive our home lifts because they are:

- Reliable, proven technology

- Low-level noise, less than 50 decibels

- Maximising interior cabin space

- Energy efficient

- Smooth and quiet ride

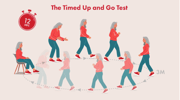

Uplifts

Uplifts by Stannah are homelifts as you’ve never seen before, they integrate the guide rails into the cabin, making the most of the space available in your home. They are available in two cabin sizes and come with a reduced cabin height option to accommodate low ceilings.

The electrically powered, reliable self-contained drive system, is located at the top of the cabin and moves your homelift smoothly and quietly between floors. There’s no need to install a motor room or hydraulic pump nearby, making it a compact solution for your home.

Both the S2 and S3 come with integrated rails within the cabin, making the best use of the space, and enhancing the style of your home. Plus, the guide rails can be positioned against the wall, leaving the area clear when the lift is on the other level. They make the most of the space available in your home, leaving your living areas free for you to enjoy when the lift is located on the other level.

Hydraulic lifts also require less headroom and allow the quiet drive mechanism to be placed up to 10 metres away from the lift, in a cupboard or even outside, maximising space on the floor, and cabin space and further minimising noise.

Running Costs and Maintenance

Homelifts are generally cheap to run, using only a similar amount of electricity as a small household appliance. Some claim that electrically powered lifts are more energy efficient than hydraulic lifts, which is true to a certain extent for counterweighted lifts. For rope and drum lifts any difference is unclear.

Some people are concerned that hydraulic lifts may come with a risk of leaking hydraulic fluid, often oil, which can be detrimental to the environment. Indeed, there is a theoretical risk but in reality, it is very rare and only as likely as rust or corroded cables on a traction lift.

The speed of domestic lifts is regulated under BS5900:2012 to 0.06m per second and both traction and hydraulic lifts can easily match regulated maximums.

Electrically powered lifts have low-level noise, which is less than 50 decibels, equivalent to the noise made by your refrigerator making it extremely quiet during operation.

Hydraulic lifts can be quiet depending on the placement of the pump unit. Sensible placement of the pump will allow the lift to operate almost silently, especially on the downward journey. Noise levels on traction lifts can vary depending on the mechanism used and the condition of the motor, rope and gear mechanism. The remote placement of a hydraulic pump also allows for ease of access for servicing.

.jpg?width=768&height=512&name=Uplifts%20(1).jpg)

All homelifts have to have some sort of safety mechanism in the very rare event that a lift free falls. Hydraulic lifts have a safety valve that regulates the flow of hydraulic fluid in the down direction. If, for instance, a pipe were to be cut, the fast flow of hydraulic oil would be stopped by the safety valve stopping the lift from free falling. An added safety element is that the large mass of oil flowing through a small hole is in itself a flow regulator. Traction lifts have alternative emergency breaking mechanisms.

What happens if there’s a power cut?

In the event of a power cut, all homelifts use a battery backup that will allow a user to descend to the ground floor but they will not be able to travel up. However, even under battery power, the safety edges on all our homelifts will still operate.

Hydraulic lifts also allow for easy manual release at just the flick of a switch. Manual release on traction and rope and drum lifts are operated by handles or wheels and often require assistance from a service engineer. For electrically powered homelifts, there is a battery backup system that ensures your return to the ground floor safely.

Whether a lift has an electrically powered or hydraulic drive has no bearing on whether it is self-supporting: virtually all compact lifts are self-supporting including all Stannah compact homelifts.

In conclusion, we see electrically powered drive systems as the perfect choice for compact home lifts.

If you’re interested in getting a Stannah homelift, our team will be happy to provide you with all the information you need. We can also arrange a free no no-obligation survey to help you decide the best option for your home and lifestyle.

With a variety of options to choose from, you can customise your homelift to compliment your home interior and best reflects your unique style.

Stay up to date

Latest Blogs

Whole Home Comfort with Stannah and HSL

Dame Zandra Rhodes x Stannah: When accessibility meets style

Could more people benefit from home adaptation support for hidden disabilities?

50 years of Stannah Stairlifts – A milestone grounded in purpose

BBC’s Dr Punam Krishan reveals a little-known Parkinson’s symptom to watch for...

Are you at risk of falling? Dr. Punam Krishan’s simple 12-second test could tell you...

Snore Wars: Could sleeping separately be the secret to a better night’s rest?

Proud to carry the Made in Britain mark!

Stairlifts made for you

All our stairlifts whether straight or curved are customised to suit you and your home so call now to arrange a visit to get your FREE personalised quote!